The Glassbox Warehouse

Operating smart and transparently

Speedy, error-minimized and cost-effective logistics are critical to success. The transparent and smart logistics center supports these goals by measuring success criteria and correlations in equal measure, highlighting errors and possible causes, and identifying and reporting special features.

Transparent, as key figures are available to both operations and management at all times.

Smart, as special cases and challenges are identified and justified independently.

Through an uncomplicated connection to your Warehouse Management System (WMS), we provide transparency about lived, adapting processes.

We are happy to explain details in a non-binding conversation and without investment: the first process graph is on us.

This is a transparent logistics center – Transparency about real processes

Logistics processes are structured, can be planned well and offer little scope for deviations thanks to conveyor technology. The reality shows that operating errors, failures and special requests, or simply a piece of goods missing from the conveyor system undermine the target processes. The workforce creates the short path to the outgoing goods department to meet the situation. Many such processes are already “known”, but their impact is not. We have already generated aha experiences on several occasions with this transparency in logistics processes. The basis for this is the lived process variants of how goods reach the shipping department from goods receipt – or when they do not. The thought “That can’t be!” will certainly cross your mind.

40% less delays after a few weeks of analysis? – Understanding Root Causes

Delayed or unshipped goods are one of the biggest challenges in a LC. The causes are many and often individual in nature. A transparent LC measures metrics and shows characteristics of delayed processes in context. It shows you how high the proportion of structural causes of these problems really is in relation to “bad luck”. Where do structural problems lead to delays and under what conditions? With this information, you can target workflows or optimize IT and then measure progress – automatically.

Everything in view – Automated common sense

Even without existing process models, we provide an exact graphical representation of all process variants. The exact flow of individual goods is formalized and displayed via dashboard. The target process is usually clearly visible, but also many deviants of all possible situations. With this database, an anomaly detection evaluates every single flow of goods for its regularity. A dashboard shows you the deviant processes that are worth thinking about.

The results and visualizations are integrated into your existing daily reports on request and we support you in this process. Our tool serves standardized interfaces to e.g. PowerBI, Apromore or Knime. In addition, we offer our own solution for individual requirements.

Examples – what do the results look like?

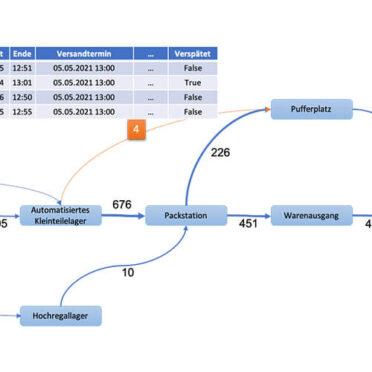

The basis is always the booking paths on which goods pass through your logistics. They follow your target process or can also deviate from it. The first figure shows the process variants of a day aggregated to the larger warehouse areas. In practice, the detail level goes down to individual activities. Looks chaotic? Yes, your LC is even more complex – guaranteed! The second figure filters tour T1 and selects the characteristics of the unusual process step from the warehouse to the buffer bins. Still not variant enough? The third figure shows the automated anomaly detection and selects a process variant that first follows the target process, but then books from the gate into the goods receipt and still makes it into the truck. Surely you do not experience such process variants and if you do, you know the reasons?

For the human eye, the diversity of process variants is often impossible to penetrate. The trick is to use process mining and Explainable AI methods to look in the right place right away.

Detailed application examples can be found in this article and in our blog (both in German).

Our digital scrum master (Research in Progress) is also based on the same technology.

Prerequisites

We can generate the fastest results if they use a variant of the Körber / Inconso WMS. We also encounter other WMSs on a regular basis. Our tool requires access to the WMS database or a targeted export of specific tables, and working on an archive system is also useful for initial insights.

As an execution environment, we can use any cloud, ours, or your on-premise infrastructure – as needed.

We offer the analysis step as a ready-made package. An individual effort arises with the connection to your reporting or through individual analyses – also gladly together with your team.